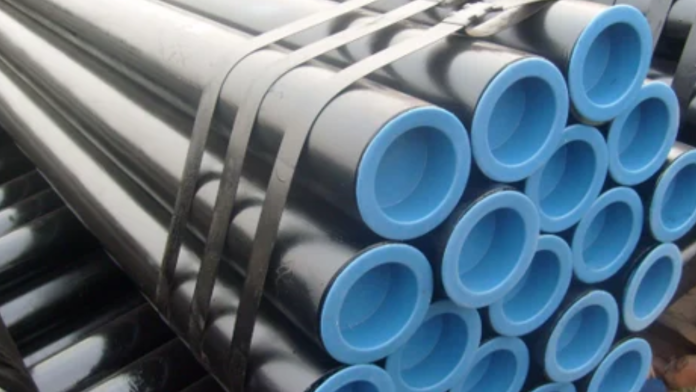

The EN 10217-1 standard is an urgent component of European directions overseeing welded weight channels, particularly laying out the technical necessities for carbon steel tubes. Through its comprehensive rules, this standard streamlines the creation and arrangement of welded carbon steel tubes with assigned room temperature properties and rated weights. This standard ensures that carbon steel tubes meet rigid criteria concerning their mechanical properties and auxiliary judgment, basic for their secure and compelling utilization in different applications.

By giving clear and nitty gritty determinations, en10217 encourages manufacturing preparation while ensuring consistency and quality over distinctive generation offices. EN 10217-1 serves as a foundational system for the manufacture and utilization of welded carbon steel tubes in weight channeling systems. Its rules contribute to the general security, reliability, and execution of these tubes, making them fundamental components in businesses such as oil and gas, petrochemicals, and control era. Compliance with EN 10217-1 is basic for manufacturers and clients alike to maintain industry guidelines and guarantee the astuteness of weight channeling frameworks.

Outline of EN 10217-1 Standard

EN 10217-1 stands as the European standard overseeing the manufacture of welded weight channels, particularly custom fitted for carbon steel tubes. These tubes are utilized in different businesses, including oil and gas, petrochemicals, and control era. Compliance with this standard is basic to guarantee the basic judgment and unwavering quality of weight vessels and channeling frameworks.

Key Requirements of EN 10217-1 Standard

The necessities outlined in EN 10217-1 envelop basic parameters such as least surrender point quality, tensile quality, stretching, weldability, affect values, and non-destructive testing strategies. These details are imperative for guaranteeing the performance and security of carbon steel tubes under different operational conditions.

Application in Businesses

EN 10217-1 finds widespread application in developing weight vessels and piping frameworks over different businesses. Within the oil and gas division, these tubes are indispensable in pipelines, refineries, and seaward stages. Additionally, the petrochemical industry utilizes them for transporting and preparing chemical substances. Furthermore, the control era division depends on these tubes for steam and water conveyance inside control plants.

Compliance and Quality Confirmation

Compliance with EN 10217-1 requires exacting adherence to indicated manufacturing forms and quality control measures. Producers must guarantee that the manufactured carbon steel tubes meet stipulated mechanical properties and dimensional resiliences. Quality confirmation strategies, counting material testing, welding assessments, and non-destructive testing, are basic to confirm compliance and maintain item quality.

Benefits and Focal Points

The selection of the EN 10217-1 standard offers a few benefits to businesses included in weight channeling frameworks. Firstly, it gives a standardized system for carbon steel tube creation, advancing consistency and interoperability. Also, compliance guarantees the basic keenness and unwavering quality of weight vessels and channeling frameworks, upgrading operational security and effectiveness.

Future Advancements and Contemplations

As innovation propels and industry necessities advance, EN 10217-1 may undergo revisions and overhauls to adjust to rising patterns and hones. Persistent change and adjustment are significant to address advancing challenges and optimize tube execution in different applications. Contemplations such as natural supportability and vitality effectiveness may impact future advancements in tube creation and utilization.

Conclusion

The EN 10217-1 standard plays an essential part in overseeing welded carbon steel tubes for weight channeling frameworks. By indicating necessities and quality affirmation measures, it guarantees the unwavering quality, security, and execution of these tubes in differing mechanical applications. Compliance with EN 10217-1 is imperative for keeping up item quality and operational astuteness in weight vessel and channeling frameworks.